Gravimetric dosing technology fitted for your production

Multicomponent

dosing systems

Here proven standard components are constructively combined about mixtures discontinuously

or continuously to produce.

dosing control via dosing processor DPC 3001

conveyor systems: belts, vibration channels, vibration belts and dosing screws

additional modules: distribution systems, turntable (on request)

options: customized adaptations

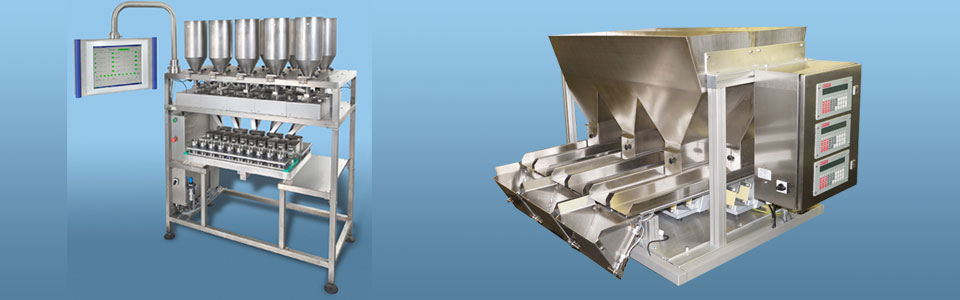

Plant here: 10-component dosing system DW 0.5 / 10K

Product: different powdersWeighing range: 15 g to 250 g

Display accuracy: 50mg

Common, mobile base frame made of stainless steel,

10 pieces of material hopper with appr. 10 liters volume

material hopper with quick-change device

material hopper with coding,

dosing system: rough/fine dosing channels with vibrators,

(mounted in boxer position)

vibrators encapsulated with stainless steel cover,

electronic weighing system DW 0.5 with pneumatic discharge

(load cell with encapsulated stainless steel cover)

weighing pan with appr. 360 ccm volume,

Cradle with removable grid box for 10 customer-side container (for 10 components)

Pneumatically operated moving part to retract the container:

Pos. 1: retraction of the glasses in the metering unit

Pos. 2: position the container below the outlet ducts,

cradle and mesh boxes made of stainless steel.

all product touching parts in stainless steel V2a (material no: 1.4301).

dosing processor DPC3001 to control dosing system DW 0.5 / 10KDosing processor in cabinet in stainless steel (IP 54)

operating housing (swiveling) made of stainless steel for 19 "touch screen and PC,

Recipe management KTG2.3 with storage, possibility for 200 recipes,

Interfacing with RS232 and interface protocol KTG0.4 to communicate with the host PC,

Communication module for connection to processors DPC 3001,

Start button,

Emergency stop button,

Remote Maintenance with DSL connection,

Voltage 230V / 50Hz,

CE-tested according to industry standard.

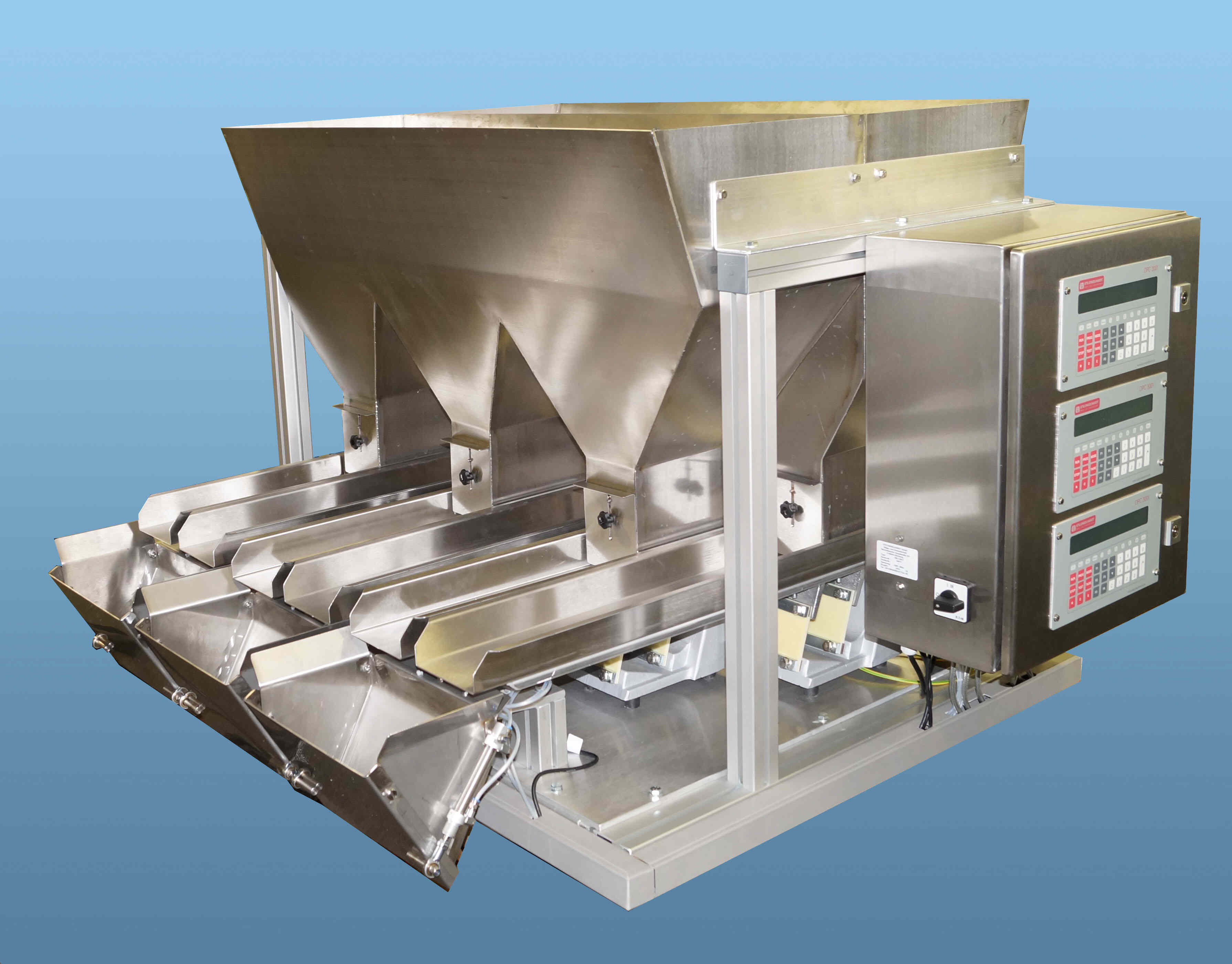

Multicomponent 6-fold dosing system

Aluminum profile frame

2 x hopper with two outlets,

6 x dosing system: rough/fine dosing channel with vibrator,

3 x electronic weighing system with automatic discharge,

3 x weighing pan with appr. 3000 ccm volume

all product touching parts in stainless steel V2a (material no: 1.4301).

cycle time: appr. 5 weighments per minute/ for two components

dosing control via dosing processor DPC 3001

(here in stainless steel control box)

performance and

accuracy

specifications

are

depending on the

product

4-component dosing weigher

Plant construction here:4 x hopper with appr. 30 litres volume,

4 x dosing system: rough/fine dosing channel with vibrator,

1 x common conveying channel with vibrator

1 x common discharge chute

2 x electronic weighing system (oil damped) with automatic discharge,

2 x weighing pan with appr. 5000 ccm volume

dosing c

150 program memory - recipe management (customized)

performance and accuracy specifications are depending on the product

Continuous multi-component system for extruder feed.

Here shredded recycled materials and raw materials are percentage weighed and continuously discharged.Plant construction here:

2 x dosing system: rough/fine dosing channel with vibrator,

1 x feeding channel with vibrator and control flap

1 x common conveying channel with vibrato

1 x common discharge chute

2 x electronic weighing system with automatic discharge,

1 x weighing pan with appr. 2000 ccm volume

1 x weighing pan with appr. 5000 ccm volume

all product touching parts in stainless steel V2a (material no: 1.4301).

capacities here: – 300 kg/h

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending on the product

Telefon: 0911 - 96 44 936 Telefax: 0911 - 96 44 938 E-Mail: info@ktg-engelhardt.de www.ktg-engelhardt.de

| Contact | Location | Imprint | AGB's |